In ceramic tile manufacturing, planarity – the ability of a tile to stay perfectly flat after firing is the ultimate mark of technical precision. Even a slight curvature can cause visible lippage, uneven reflection, and poor adhesion during installation. The challenge becomes even greater as tiles grow larger, thinner, and glossier.

Perfect flatness is not achieved by chance. It depends on how the three main layers of a tile – the body, engobe, and glaze – expand and contract under heat. When their thermal movements do not align, the tile bends. This bending, known in production as a tile “going bananas”, is the physical result of thermal expansion mismatch.

The Body – The Foundation and the Thermal Driver

The body forms the structural backbone of a ceramic tile. It is made from clays, feldspars, carbonates, and sand, which together define both its strength and its thermal behaviour.

A key factor is the sand content. Bodies with higher sand content exhibit greater thermal expansion. This means sand-rich bodies expand and contract more during firing and cooling, increasing mismatch with the upper layers.

In short, the body’s composition dictates how much the tile will move thermally. The higher the quartz proportion, the greater the expansion and the higher the risk of curvature if the surface layers cannot follow the same rhythm.

The Glaze – A Glassy Surface with Lower Expansion

The glaze provides the tile’s colour, gloss, and surface protection. Chemically, it is a glass composed mainly of silica, alumina, and fluxes. Its thermal expansion is generally lower than that of the body due to its high glass content.

Glossy glazes, in particular, have even lower thermal expansion because of their higher glass content. When a glossy glaze is applied over a sand-rich, high-expansion body, the mismatch between body and glaze increases.

As the tile cools, the body wants to shrink more, but the glassy glaze resists this movement. The result is stress due to tension in the body and compression in the glaze. The tile therefore bends upward (moons upward), forming a convex surface.

The greater the difference in expansion between the body and the glaze, the more pronounced the curvature. This is why glossy tiles are more difficult to keep flat compared with matt tiles.

The Engobe – The Balancing Layer

The engobe is a thin layer applied between the body and the glaze. It improves surface uniformity and colour consistency, but its most critical function is thermal balance.

The engobe is formulated so that its coefficient of thermal expansion (CTE) lies between that of the body and the glaze. This middle-ground behaviour allows it to absorb stress.

When designed correctly, the push of the engobe (which tends to bend the tile downward) perfectly balances the pull of the glaze (which bends it upward). The tile emerges from the kiln flat and stable.

Understanding Curvature: The Bimetal Strip Analogy

To visualise this behaviour, think of a bimetal strip used in thermostats. It is made of two metals with different thermal expansions. When heated or cooled, one expands or contracts more, causing the strip to bend toward the side that expands less.

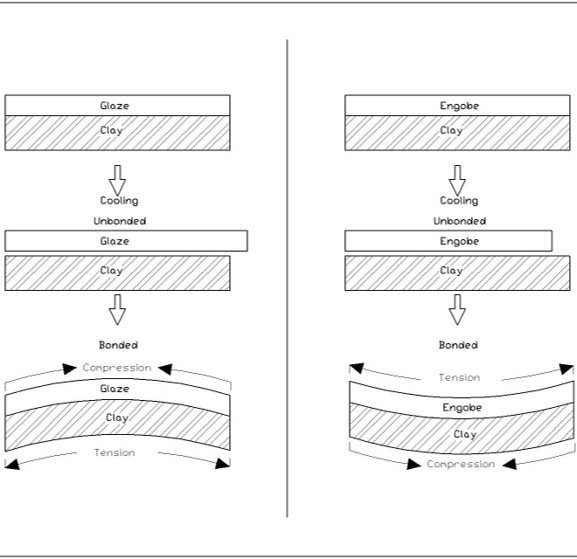

A tile behaves the same way. The glaze, engobe, and body are like layers of different metals, each expanding and contracting differently during firing and cooling. Here is a classical set of experiment to see this effect.

Experiment 1: Body with Glaze (No Engobe)

When a tile is fired with only glaze over the body, the glaze contracts less than the body during cooling. The body, trying to shrink more, pulls from below, and the tile cups upward (convex).

Experiment 2: Body with Engobe (No Glaze)

When only the engobe is applied, it usually expands slightly more than the body. On cooling, it contracts more strongly, and the tile cups downward (concave).

Experiment 3: Body + Engobe + Glaze

With all three layers correctly balanced, the stresses cancel out. The glaze’s pull and the engobe’s push reach equilibrium, keeping the tile perfectly flat.

Firing as a Corrective Measure: Differential Firing

Differential firing acts like a fine-tuning tool. By slightly changing how much each face expands and contracts, engineers can correct thermal mismatches that would otherwise distort the tile. For glossy, large-format tiles, these adjustments are essential.

In roller kilns, tiles are exposed to temperature gradients that can either create or correct curvature, depending on how heat is applied. If the top surface (glaze side) cools faster than the body, the glaze solidifies under compression while the body continues to shrink, producing upward curvature. Conversely, if the bottom side cools faster, the tile bends downward.

Manufacturers counter these tendencies using differential firing – the deliberate adjustment of heating and cooling between the top and bottom of the tile.

Achieving Planarity: The Equation of Balance

1. Composition:

- Higher sand content increases body expansion.

- Glossy, high-glass glazes have lower expansion.

- The engobe must be formulated between the two to distribute stress.

2. Layer Thickness:

- Excessive glaze or engobe thickness magnifies stress.

- Optimal balance depends on body formulation and tile size.

3. Firing Control:

- Differential firing and cooling can offset thermal mismatch.

- Precise control of heat gradients is vital for large, glossy tiles.

4. Geometry:

- Larger tiles need tighter control of temperature and consistency.

The Bottom Line: Planarity Is Engineered Precision

A perfectly flat tile is not a coincidence; it is the result of meticulous control over chemistry, thickness, and thermal behaviour.

When the sand-rich body expands more than the low-expansion, high-glass glaze, curvature forms. The engobe corrects that mismatch, while differential firing fine-tunes the stress balance, ensuring both surfaces expand and contract in harmony.

In the end, planarity is not just about aesthetics, it is proof of mastery over materials, heat, and physics.